Following my stay in the Department of Civil Engineering and Applied Mechanics from McGill University (Montreal, Canada) and my collaboration with SB Savage, we continued our studies on a numerical model of granular media subjected to cohesive forces (Model molecular dynamics). This model allows to describe exhaustively the micro interactions taking place between the grains. We used the laws of mechanical behavior typically allowed in these models. The grains may intersect and thus oppose a force proportional to the normal overlap but delayed by a carefully chosen shock (hence the name « Spring-Dashpot ») to avoid the effects of oscillations such as sound propagation .Similarly, the tangential forces are defined by a coefficient depending on sliding tangential grain and similarly depreciated. In addition, the tangential forces are governed by the Coulomb criterion when the contact is purely sec. The addition of cohesion forces can generate the tangential greater.

This model has thus to simulate the behavior of ice floes (ice block wide but thin) subject to the currents. By extension, in this model we can introduce elements consist of several grains which initially glued break under the action of external loads (due to shear currents, Coriolis, wind, etc. …..) but also elements that weld is under compression (agglomeration of ice blocks mechanically or thermally). These results are analyzed and modified according to parameters obtained from experiments « size » made in the centers of ice of Canada (NRC Newfoundland). Preliminary results on two-dimensional piles subjected to biaxial compression have showed that the overall coefficient of friction of a pile was almost constant irrespective of the value of the coefficient of friction between grains. This is in contradiction with the generally accepted theories in soil mechanics (Caquot, Bishop Rowe, etc …) have proposed a linear dependence between these two parameters. Similarly, the overall friction coefficient is never zero even if the value of the coefficient of friction between the grain is the geometric dimensions playing the role of low shear stresses.

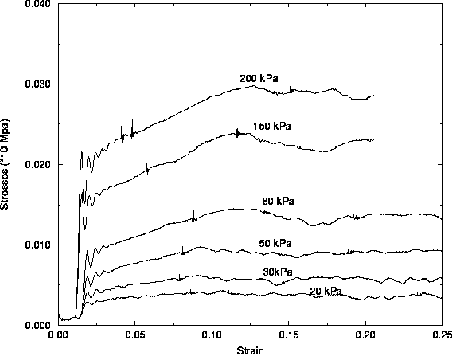

Figure: Force displacement during a biaxial test with different values of confinement (between 20 and 200kPa).

We have shown that the friction coefficient increased with the overall growth of the distribution of grain sizes. . Indeed, the appearance of areas more or less geometrically ordered causes the transmission of contact forces over large correlation lengths and thus distorts the overall coefficient of friction (decrease). The anisotropic distribution of contact forces due to biaxial compression is not compensated by a uniform distribution of directions of these forces.